Cleaning Equipment

Highlights

Automatic cleaning and inspection operation (no operator required in the reactor pit)

Self-propelled and remote-controlled (reduction of critical time and thus operator stress)

Thread monitoring and tracking of the thread condition

Stud hole cleaning machines for the reactor pressure vessel

Based on customer service feedback, the manufacturer has recognized the need to carefully maintain and inspect the stud hole threads of the reactor studs. This involves cleaning the stud hole threads of hardened grease so that the threads can be inspected and, if damaged, reworked to ensure that the reactor bolts can be screwed in safely and without problems.

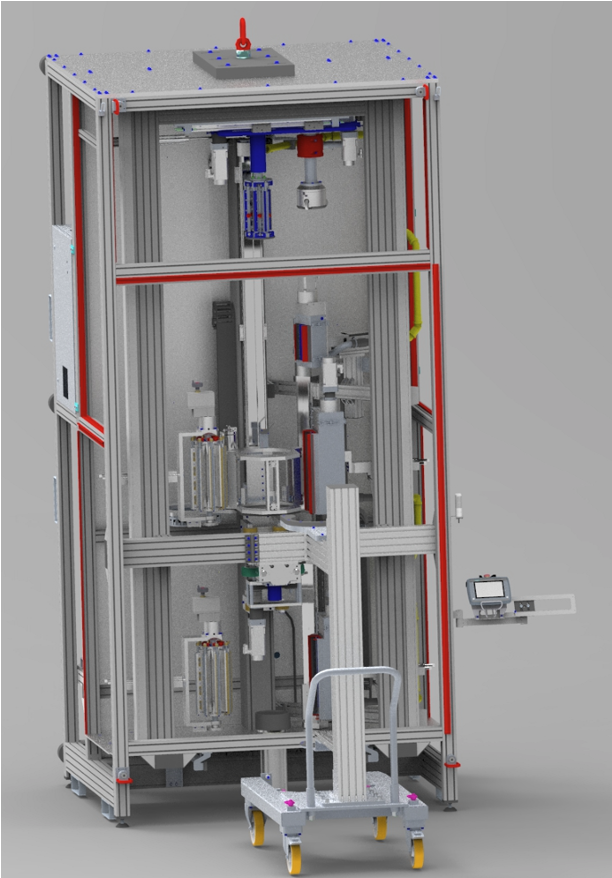

You can choose between simplified cleaning devices and automated cleaning machines:

- The simple version of the stud hole cleaning device works with a purely pneumatic brush module. The brush head is driven pneumatically and the lifting movement is carried out by a pneumatic cylinder. The device is placed on the reactor vessel flange by two people and operated on site. In addition to the cleaning device, a suction device must be connected during the cleaning process. The device is moved from one stud hole to another by hand. It is also possible to move the appliance using a rotary crane. The appropriate lifting points for transportation are provided on the cleaning device.

NIS has also developed a stud hole cleaning machine in a modular design in order to adapt the machine to the specific requirements of the customer. The stud hole cleaning machine is controlled and operated from a control panel at the edge of the reactor pit. The modules of the stud hole cleaning machine are built on a self-processing platform. The movement of the platform is automated with the aid of two walking units attached to the right and left of the platform. Moving and positioning on the reactor vessel is carried out in such a way as to ensure that the machine does not tip over during the process or cleaning.

The electrical cabinet with the control technology is mounted on the platform. The suction device with the HEPA filter is also mounted on the platform. The suction device is directly connected to the brush module so that the dust particles that occur during dry cleaning are extracted directly via the brush head.

The suction system prevents contaminated dust particles from entering the environment and being carried away. Depending on customer requirements, stainless steel or nylon brushes can be used.

Other options for stud hole cleaning include a thread inspection module (high-resolution camera) and a module for greasing the stud hole threads. The two modules are built on a separate platform so that the cleaning process of the stud holes is not disturbed by the inspection or grease module.

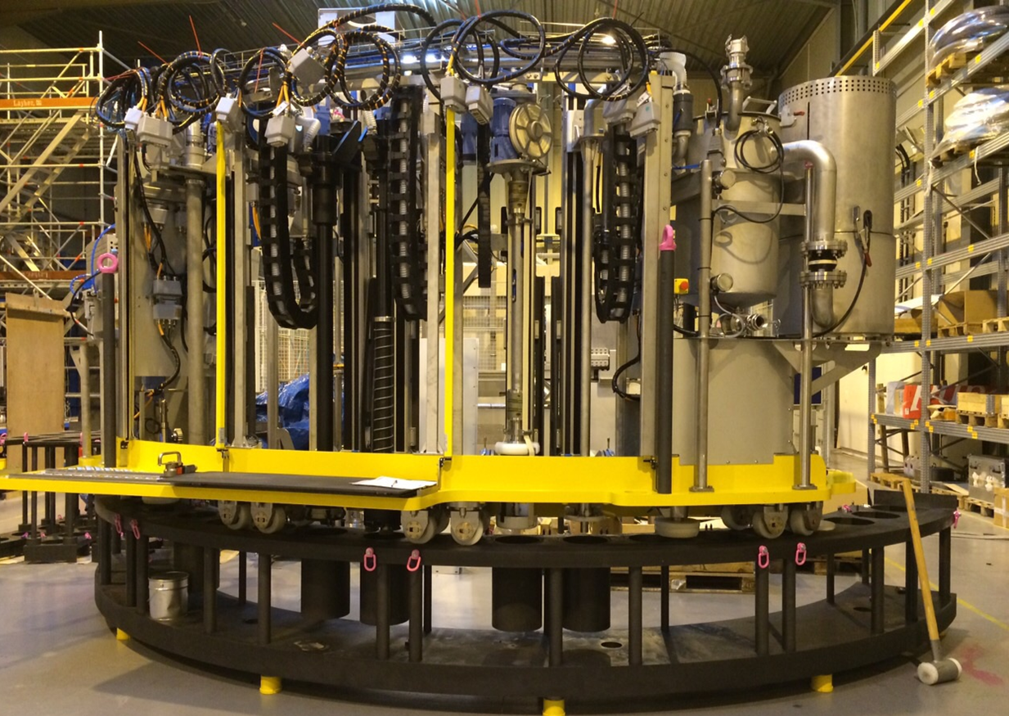

RPV Stud cleaning - New Generation

The system has an integrated lifting system and enables the cleaning of RPV bolts including nuts. The automated process sequence can be stopped at any time to carry out inspections and then continued by simply restarting it.

The threads of the bolts are cleaned of hardened grease using brushes. An RPV nut unwinding and winding device, a degreasing unit and a greasing module are available for this purpose. The latter can be parameterised for greasing the upper and lower part of the bolt thread.

The precise control system ensures that the RPV nuts are wound onto the RPV studs in exactly the right position. An integrated extraction system is also available to ensure clean working conditions.

The system can be flexibly adjusted to different stud sizes and weighs less than 3 tonnes in total. It can be transported both horizontally and vertically and is highly versatile.

Important aspects are:

- Optimisation of time on the critical path

- When cleaning the bolts, the operators are protected from contamination (encapsulated cleaning)

- The RPV bolts are protected from damage during cleaning

- The RPV bolts are cleaned dry. Only dry contaminated dirt accumulates

- Less than 3m² of storage space required

- Easy screwing in of the RDB bolts with the screwdriver